ATEK Drive Solutions

The top supplier of customised system solutions for drivetrains by developing high-quality brakes, gears, and servo motor technology in small batches that can offer versatile customisation, integration, and use.

Portrait

From component manufacturer to system provider

ATEK Drive Solutions GmbH is a young company with decades of experience in drive technology. This is not a contradiction but the result of the merger of two traditional component manufacturers within the Obermark Group: Deutsche van Rietschoten & Houwens GmbH as the provider of know-how for industrial brakes and ATEK Antriebstechnik Willi Glapiak GmbH as the provider of expertise in gear construction.

In 1961, the two Dutchmen Schuit and Felix Biewer founded Deutsche van Rietschoten & Houwens in Hanover, initially for the export-driven trade of woodworking equipment. From 1963 onwards, the company also marketed industrial brakes. In 1976, the first in-house developed brake model was launched onto the market. Since then, both the product portfolio and the fields of application worldwide have seen steady expansion.

The origins of ATEK Antriebstechnik date back to 1939 when Willi Glapiak opened a small contract turning shop in Hamburg. In 1983, Willi Glapiak GmbH merged with ATEK Antriebstechnik GmbH, and the company’s headquarters were moved to Rellingen. In the same year, the newly formed company produced the first bevel gearbox at the request of a well-known coffee roaster. Since then, the company has grown in this sector and launched a vast number of new gearbox models.

In 2011, the Obermark Group acquired Deutsche van Rietschoten & Houwens GmbH and eight years later, in 2019, ATEK Antriebstechnik Willi Glapiak GmbH. In 2023, the locations of the two companies were consolidated in the context of a cooperation, and then in 2024, the two companies merged to become ATEK Drive Solutions GmbH. And with this additional and newly established expertise in the manufacture of servo motors, ATEK Drive Solutions has responded to changes on the demand side of the market, moving away from individual components towards offering system solutions for the drive train.

Sebastian Sturm is the Managing Director of ATEK Drive Solutions GmbH. Prior to the merger, he held this position at Deutsche van Rietschoten & Houwens GmbH and ATEK Antriebstechnik Willi Glapiak GmbH at the same time

Application

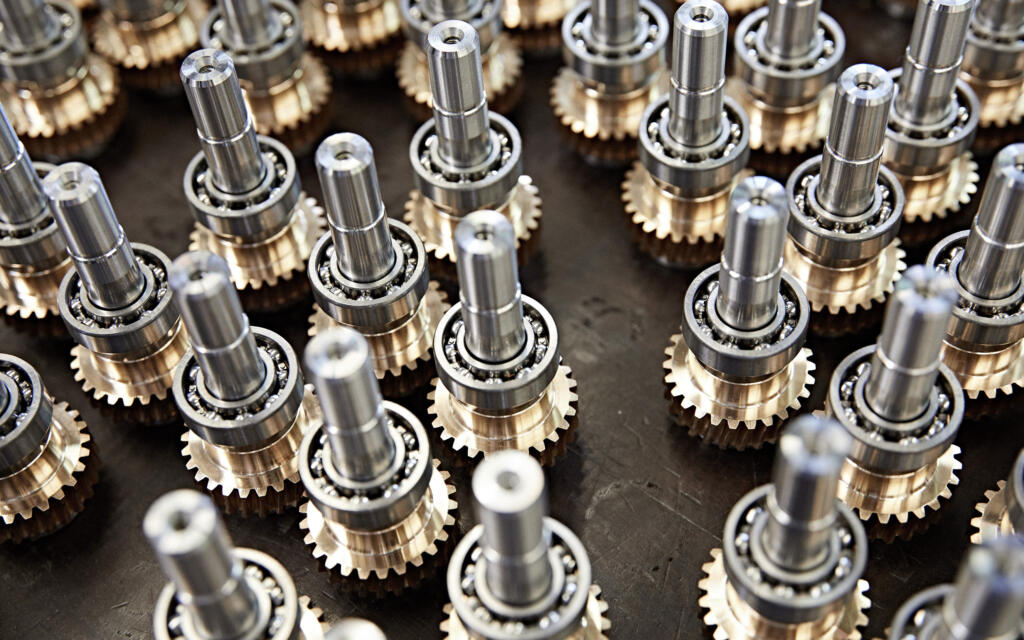

ATEK Drive Solutions offers a modular system and innovative customized solutions at an exceptionally good price-performance ratio and fast delivery times. This is achieved by a modern digital infrastructure and an inventory of almost 400,000 individual parts.

This enables ATEK Drive Solutions to build millions of different solutions consisting of brakes, gears, and motors – as a specific individual component, a proven series product, or a highly integrated system solution used in applications ranging from clean rooms in the pharmaceutical industry to coal mines. The products include top-quality angular, angular planetary as well as hypoid and worm gearboxes; mechanical, pneumatic, hydraulic and electric brakes as well as the latest generation of top-performance servomotors.

In 2024, ATEK Drive Solutions launched the first gearboxes with integrated servomotors and electrified lever brakes. Moreover, the existing brake portfolio was fully electrified.

Application I – Gearbox technology

Angular gearboxes show their strengths, for example, in areas such as packaging systems. Due to the right-angled power transmission, the drive motors can be arranged in the systems in a space-saving manner. In the food and in the pharmaceutical industry, special stainless steel designs also meet the strict hygiene regulations. Stainless steel does not react with common cleaning agents or disinfectants and does not release particles when subjected to stress – food, liquids, and other organic substances are therefore not contaminated. The gearboxes are used as drives for simple conveyor belts, dosing adjustments, and even cheese graters.

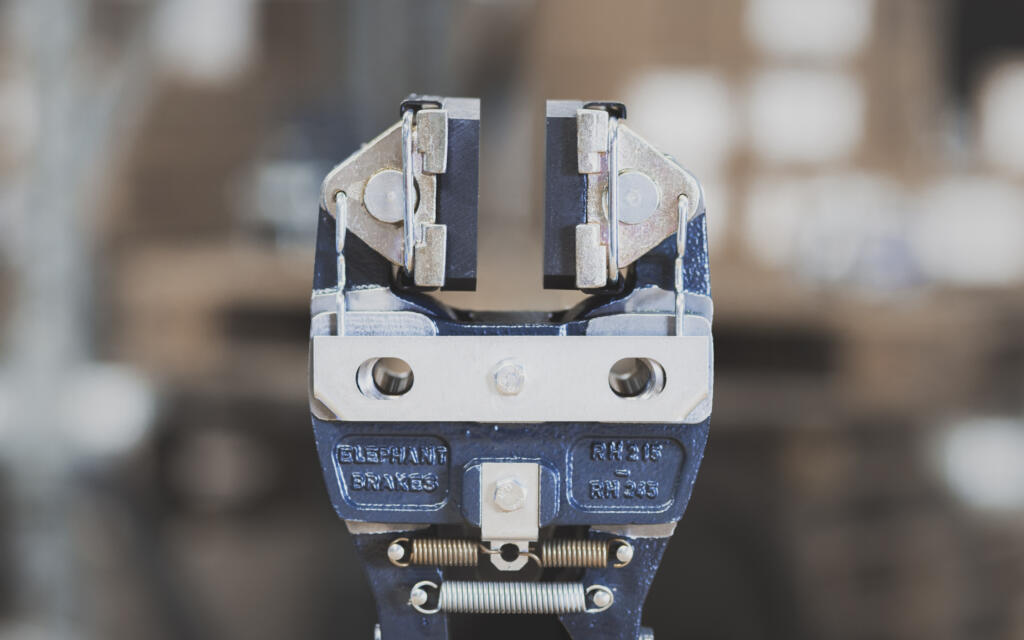

Application II – Brake technology

In the food industry, precise brake mechanisms are required to control systems reliably and safely. The use of industrial brakes in cheese graters can serve as an example, where high accuracy and control are key. An industrial grater for the mass production of grated cheese operates at up to 3,000 revolutions per minute (rpm). At these high speeds, precise control is required to stop the system if necessary, for instance in the event of a material jam or overload. In particular electromagnetic or hydraulic industrial brakes powered by Rietschoten are designed to slow down or completely stop the rotary movement of the machine with precision in fractions of a second. With their braking power, they can slow down loads of several hundred kilograms up to several tons. This is necessary because the rotors and cutting devices of the cheese grater are enormous rotating masses that develop considerable forces in the event of a sudden stop.

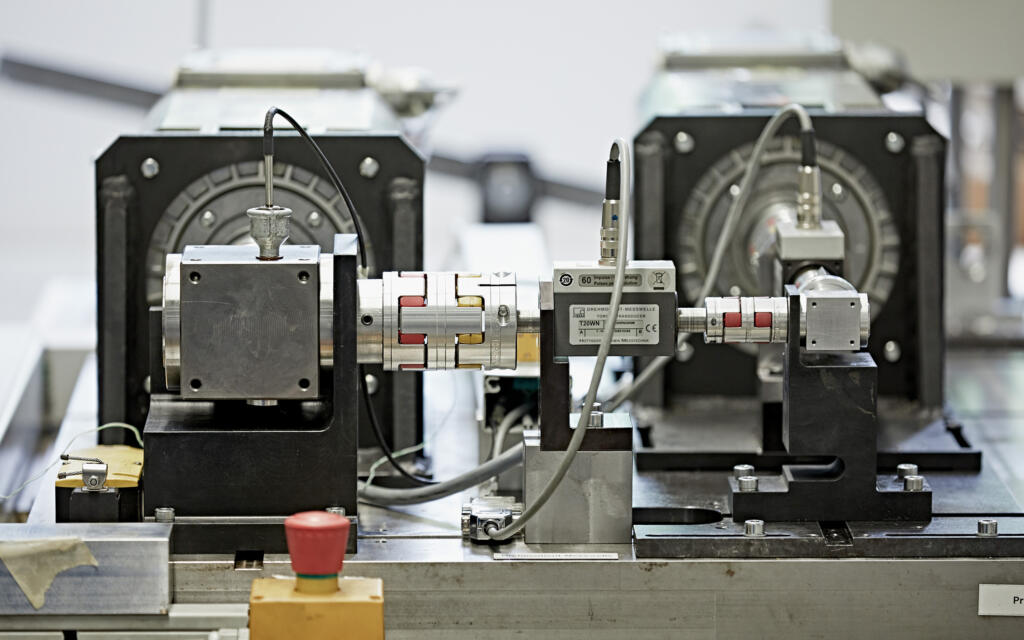

Application III – Servomotor technology

Small, compact drive units that are operated in autonomous vehicles with battery packs are a new challenge for drive technology: an important goal is weight optimization, which is achieved through high packing density and drive units that are as compact as possible. Manufacturers in intralogistics continue to demand fast response times, encoder systems, and functional and space-saving designs for use in automated storage systems, so-called shuttles. The geared motors are used as travel or lifting drives that pick up packages of up to 30 kilograms from the various storage locations and transport them to a transfer position.

Markets

ATEK Drive Solutions GmbH produces at its site in Rellingen. With a broad-ranging direct sales network, the company operates nationwide across Germany and generates two thirds of its revenue there. The vast majority of the marketed products are built into systems, 90 per cent are destined for export. In the international markets, the company grows through co-operation with trading partners. The focus is on the European markets, China, and the USA. In the future, ATEK Drive Solutions also plans to establish structures for a direct sales network in foreign markets. In addition to the aforementioned markets, the focus will also shift to India and the countries of South East Asia in the medium term.

In terms of sectors, the company offers solutions for manufacturing companies in numerous industries. These include in particular logistics and warehousing, shipbuilding, renewable energies, mining, construction and the food industry.

Insights

Every company and each employee are unique and have a distinct history. The following texts offer an impression of the motivation, perspective and convictions of the people behind the stories.