Holzhauer-Pumpen

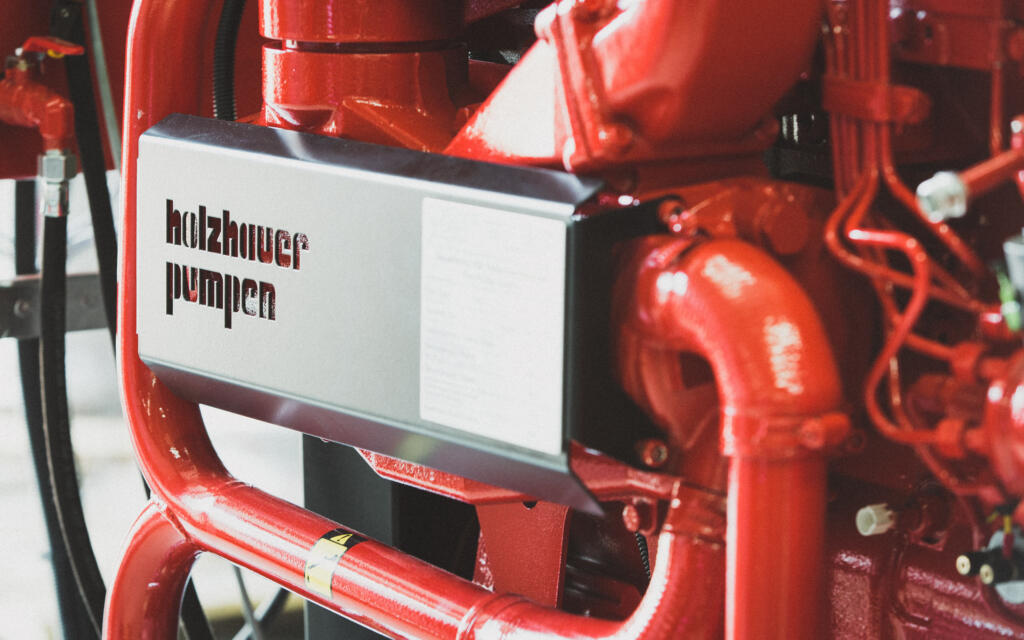

Holzhauer-Pumpen develops and manufactures complete pump stations. They are utilised globally, and in the case of a fire, provide a safe supply of extinguishing water even under the most extreme conditions.

Portrait

Compact for success

Hardly anyone sees Holzhauer pumps, despite them being used everywhere where large groups assemble or where assets with high economic value must be protected: airports and train stations, factories and industrial plants, office buildings, stadiums, hotels, oil and gas production sites.

In an emergency, Holzhauer pumps ensure that enough water is available and travels through the pipes at the right pressure to supply many thousands of sprinklers or other extinguishing equipment. The pumping stations are designed and constructed to withstand heat, power failure, earthquakes or blast waves.

Almost 40 years ago, Holzhauer first brought self-developed pumping units in a new compact design to market. Today, the company is the market leader in this segment. The prefabricated pumping stations are completely designed, built and tested at the company’s plant in Karben, Germany. The customers take delivery of ready-to-use and ready-to-connect stations. Holzhauer takes into account all required fire protection standards and regulations during the manufacturing and assembly process. On site, the assembled and certified unit simply plugs into the water supply.

Applications

Explosion-proof

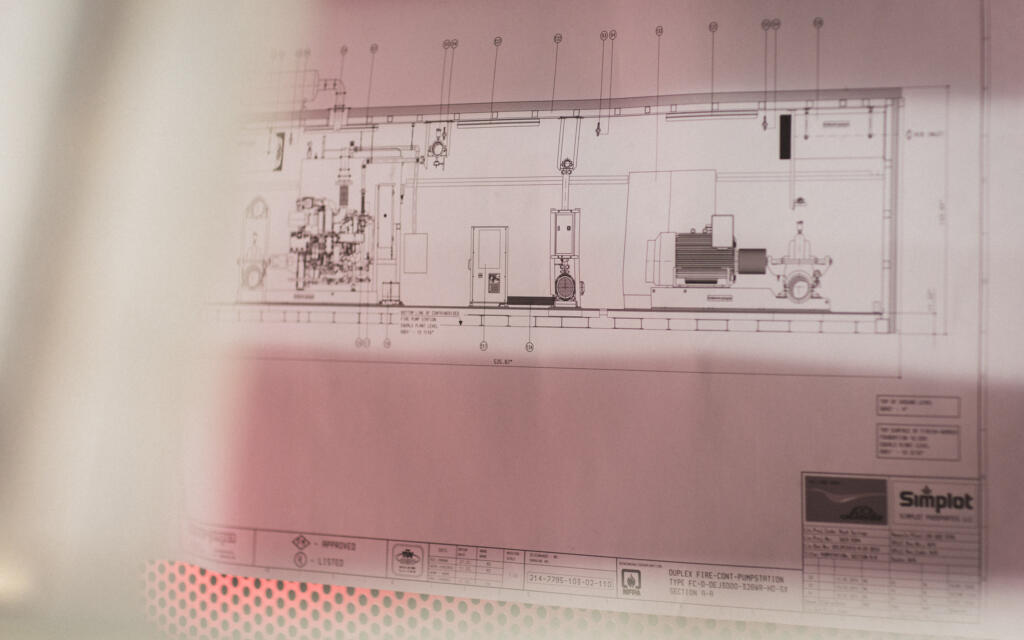

The water pumping station for a chemical plant must be particularly resilient and absolutely failsafe. In the case of a fire, pressure waves resulting from explosions are possible as is the development of extremely high temperatures. In 2015, Holzhauer delivered such a station to a customer in Wyoming, USA. Holzhauer-Pumpen fully engineered the system and shipped the completed 20-ton unit cased in steel containers, which then simply had to be connected to the extinguishing water reservoir on site.

The prefabricated pump station had to ensure the extinguishing water supply would function without restriction at temperatures as low as minus 40 degrees Celsius and at an altitude, in the Rocky Mountains, of 2,300 meters above sea level. Further, the station can withstand blast waves of up to 50 mbar per square meter of external surface; it is heated, ventilated, soundproofed, earthquake resistant and illuminated.

Construction of the station took more than two months. On-site installation, under the direction of a Holzhauer engineer, took two weeks from start to finish. Sales volume was more than one million euros. The necessary static and earthquake certification documentation, fully compliant with US standards, was more than 2,600 pages long. The German technical inspection association (TÜV) verified these technical certificates prior to clearance by the relevant authorities in Wyoming.

Markets

Specialty units around the globe

The main markets for Holzhauer pumps are Germany, Austria, and Switzerland. The company is the market leader in these countries. In Turkey, Hungary, and Iran, Holzhauer-Pumpen operates with dedicated representatives. Furthermore, the company delivers specialty aggregates all over the world, with a focus on Europe, the Middle East, as well as North and South America.

Insights

Every company and each employee are unique and have a distinct history. The following texts offer an impression of the motivation, perspective and convictions of the people behind the stories.